(11 am. – promoted by ek hornbeck)

Burning the Midnight Oil for Living Energy Independence

I’ve mentioned several times that there are lots of Federal Rail Authority regulations that are impediments to developing sustainable transport in the United States.

I’ve mentioned several times that there are lots of Federal Rail Authority regulations that are impediments to developing sustainable transport in the United States.

One of these is in the area of “superelevation” and “cant deficiency”. Superelevation is the term used in railroading for the degree of banking provided in a turn. Just as banking a turn on a road makes it possible to take the turn at a higher speed more safely, banking the track on a railroad line makes it possible to take a turn at higher speed more safely. In US rail, its measured in the inches of the higher rail above level.

And it might seem minor technical details, but this is really critical for how much new passenger transport we can get out of our existing rail alignments for how much money.

The Basic Terms: Superelevation, Cant Excess, Cant Deficiency

When a track is “cambered”, that is to say banked in this way, there is a speed at which weight is evenly distributed between the two tracks.

At a lower speed, more of the weight is placed on the lower track. This is called “cant excess”, which is how much the bank would have to be reduced for the load to be balanced.

At a higher speed, more of the weight is placed on the higher track, which is “cant deficiency”, or how much more the upper track would have to be raised for the weight to be balanced.

Now, suppose that you have a single track that is only being lightly used by freight, and you want to take advantage of that by adding some passing track ~ say 1 mile of passing track on average for each 5 miles of track ~ to increase the capacity of the corridor to maintain the same freight train capacity and add the capacity to support passenger trains.

Now, how fast is the freight going? If this is a mainline corridor running through fairly flat terrain, carrying a large number of fairly time-sensitive freight containers from a sea port to some inland rail yard (to be hauled away by truck to the loading dock that is the final destination of the shipment), it might be rolling along at 60mph.

But suppose that its a bulk load of coal, granite, timber or any of the other high weight, low cost per ton freight tasks that are in the US travel largely by rail. It might be trundling along at 20mph. And if 20mph has a substantial cant excess, that means a lot of that up to 33 US short tons per axle load is being carried by the lower track.

Now, consider an Express intercity passenger train that we want to bring through. Since we want it to be time-competitive with Interstate driving ~ better if feasible ~ we’d like that train to be running as close to 110mph as possible.

20mph, 60mph, 110mph ~ there is no superelevation that will be anywhere close to balanced for all three. And if the heaviest freight is the slowest, if the track is superelevated at the ideal level for Express Intercity passenger trains, the result will be massive increases in wear and tear on the track because of the cant excess for slow speed freight.

Well, if you have to build that common track to avoid too much cant excess for slow speed traffic, then in turn the speed limit on the Express Intercity train through the curve depends upon the allowed amount of cant deficiency.

And if you have a choice, you put the passing track in a segment with more than the normal number of curves, so that you can superelevate that as an Express track and allow the slow, heavy freight trains to run on track with less camber.

What is it that Tilt-Trains Do?

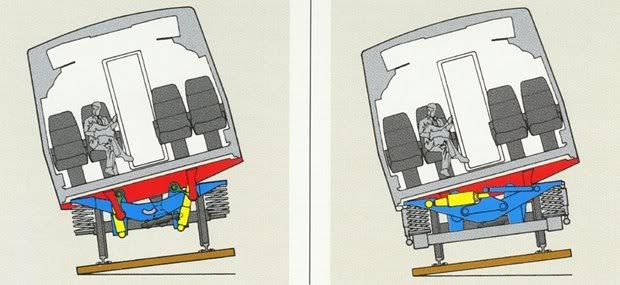

Tilt-trains effectively act to add extra camber to passenger car. This is important in that the speed that the train can safely operate on the track normally includes speeds that will throw the passengers around inside the train.

Tilt-trains effectively act to add extra camber to passenger car. This is important in that the speed that the train can safely operate on the track normally includes speeds that will throw the passengers around inside the train.

While it is partly a physical problem ~ it is also a regulatory problem.

That is, an important part of allowed cant deficiency is the matter of what lateral force passengers are permitted to experience by regulation. Since the most common European standard is 50% higher than the US standard ~ or at least, what I thought was the US standard ~ the allowable speed of the same tilt-train through a curve with the exact same curvature is substantially higher than Europe than it is in the United States.

Now, there is more to this than just the allowed lateral force passengers are permitted to experience: there is also the matter of the weight of the train. A train with 33 US short tons per axle (a common mainline maximum in the US) is putting 16.5 US short tons per wheel on the track when operating in perfect balance. A train with 25 US short tons per axle (a common European mainline maximum), is only putting 16.5 US short tons per wheel on the upper track at a cant deficiency when 66% of the weight is carried on the elevated track. And a train with 20 US short tons per axle (a shade over the maximum weight of many European and Japanese Express HSR sets), is only putting 16.5 US short tons per wheel on the upper track at a cant deficiency with 82% of the weight carried on the elevated track.

So while allowed lateral force is an important element of operating speed through curves, the weight of the train is also an important element, as noted by German rail enthusiast Hans-Joachim Zierke, in looking at the opportunities for an Emerging HSR corridor connecting California and the Pacific Northwest via the Shasta Route (and note that this is an unfinished project), when presenting the following example of the impact of FRA regulation on operating speed limits in the US:

The highest curve speeds in the USA are achieved by the Acela Express. For the track between New Haven and Boston, it has a waiver for operation at 7 inches of unbalanced superelevation. This means, that the Acela is allowed to use the same curve speed as non-tilting TGVs (or multiple units) in France.

Adding results to the comparison on page 4 gives the following table therefore:

curve radius superelevation speed limit 1 Amtrak Cascades, tilting 1000 feet 4 inches 48 mph TGV, non-tilting 1000 feet 4 inches 53 mph Acela Express, tilting 1000 feet 4 inches 53 mph Baureihe 411 EMU 1000 feet 4 inches 63 mph … In the USA, trains like the type 411 EMU are not allowed to operate. US regulations require a very high carbody strength for political reasons, which adds several tons of weight to a vehicle. If this mass is added to a European tilting EMU or DMU, it is no longer safe to operate at 11.8 inches of unbalanced superelevation, because the maximum safe axleload is exceeded.

The Acela Express is built to these strength standards. It is nearly double as heavy as European or Japanese tilting trains. Instead of restricting the axleload to 16 tons or less, the powercars weigh 25 tons per axle. No safety authority would allow values like those for the German 411 or 610 for this train, because the forces at the wheel-rail contact point would be too high for safe operation.

As a result, the “Acela Express” looses about half an hour between New York and Boston, compared to best practice in tilting train usage. (It also looses at least half an hour, compared to the calculations of US railroad engineers in the 1960s.) If this half hour of running time from New York to Boston needs to be cutted away by infrastructure investment instead, a three-digit number of millions in additional public investment will be needed at least. A similar situation will be found with almost all upgrade projects for curvy track.

In the US, the standard allowed cant deficiency of passenger rail has been set by, first, the safe operating limits of the train itself and, second, by the amount of lateral force placed on the passenger inside the train. In practice, the second is the main constraint, and this results in a much lower allowed amount of cant deficiency in the US than in Europe.

That is, even if tilt trains were acquired that were safe to operate at extremely high cant deficiencies, and which were allowed in Europe to operate at those high cant deficiencies, the existing regulations in the US would have substantially reduced the speed limit going through a curve.

The Importance of Speed Limits Through Curves

To get an idea of the importance of speed limits through curves, consider the diagram to the right. This is the modeling results (pdf) of the operating speed along the 110mph of the planned Ohio Hub 3C corridor.

To get an idea of the importance of speed limits through curves, consider the diagram to the right. This is the modeling results (pdf) of the operating speed along the 110mph of the planned Ohio Hub 3C corridor.

When the line drops all the way down to 0mph, that is, of course, a stop at a station. However, you can see all the notches where the train slows down to take a curve at a slower speed.

Consider one of the notches where speed has to be dropped down to 40mph. In the speed profile, notice that most of the time is spent dropping down from 110mph to 40mph and accelerating from 40mph to 110mph.

That is, of course, a route profile, not a trip time profile. When we think about the average speed of the service, the slowest sections of a route loom the largest.

Consider, for example, a train that runs 50 miles at 40mph and 50 miles at 110mph. A simple average of the two speeds is 75mph. But the slow section requires 1.25 hrs while the fast section requires 0.46hrs, which is a total of 100mile in 1.71 hrs, or about 59mph. More of the time is spent at 40mph, so it looms larger in the average speed.

And consider the difference between accelerating the slower leg by 10mph and accelerating the fastest leg by 10mph:

- 50 miles at 40mph and 50 miles at 120mph is 100 miles in 1.67 hrs, or ~60mph

- 50 miles at 50mph and 50 miles at 110mph is 100 miles in 1.46hrs, or ~68mph

Given the importance of the amount of slow down required through curves, the table that Hans-Joachim Zierke shows represents the US tying one hand behind its back in the race with Europe and Japan to achieve sustainable transport.

However, the Regulations May Be Fixed

OK, now. Put yourself in my shoes. I am googling around for information on cant deficiency and Federal Rail Authority regulations in mid-November, when I stumble across the following notice in the Federal Register:

Vehicle/Track Interaction Safety Standards; High-Speed and High Cant Deficiency Operations

FRA is proposing to amend the Track Safety Standards and Passenger Equipment Safety Standards applicable to high-speed and high cant deficiency train operations in order to promote the safe interaction of rail vehicles with the track over which they operate. The proposal would revise existing limits for vehicle response to track perturbations and add new limits as well. The proposal accounts for a range of vehicle types that are currently used and may likely be used on future high-speed or high cant deficiency rail operations, or both. The proposal is based on the results of simulation studies designed to identify track geometry irregularities associated with unsafe wheel/rail forces and accelerations, thorough reviews of vehicle qualification and revenue service test data, and consideration of international practices.

I was even more excited when I looked at the details of the proposal, and found that both the allowed amount of superelevation and the allowed amount of cant deficiency were proposed to be increased.

While they were looking at the regulation, they noticed a flaw in the existing regulation, and restating the regulation in terms of a design target and an allowed tolerance raises the effective maximum superelevation of track to 7in.

There is a standing balance requirement on rolling stock, since it would be unsafe to operate a train that would be in danger of tipping over if it was necessary to come to an emergency stop, so its quite possible that not all rolling stock would be permitted to use a corridor that was superelevated for Express service … but to me, you do not want every coal and granite train to qualify to enter an express bypass anyway.

For a curve with a 1000ft curve radius (which is a 5.75 degrees of curvature), under the old rules, outside of the North East Corridor, the best that could be reasonably expected would be 9″ of combined camber, from 4″ of superelevation of the track and an allowed 5″ of cant deficiency, even with a tilt train. That means that the passenger service ~ even if its a tilt train ~ would be limited to 47mph through that curve. A freight train, which is limited to 3″ of cant deficiency, and indeed all other trains limited to 3″ cant deficiency, would be limited to 41mph (those are the ~40mph curves in the above speed profile).

Why is the Northeast Corridor singled out there? Because it was granted a waiver, that allowed both the Acela tilt train and the NEC Amtrak Regional trains to operate at a higher cant deficiency than generally allowed for.

Under the new rules, which would be nationwide, if an express section of track can be superelevated to 7″, and a tilt train can operate with 8″ of cant deficiency, that is 15″ of combined camber, which would allow a express freight train to run at 49mph around the same curve, and a passenger tilt train to run at 61mph.

Under the new rules, which would be nationwide, if an express section of track can be superelevated to 7″, and a tilt train can operate with 8″ of cant deficiency, that is 15″ of combined camber, which would allow a express freight train to run at 49mph around the same curve, and a passenger tilt train to run at 61mph.

Indeed, one thing that this new regulation implies is that existing Amtrak services operating in mountainous terrain along “river routes” with the large number of curves that this implies can receive a substantial speed upgrade even before raising the top speed limit above 79mph. Also, Amtrak services that will be running on any segment of track upgraded for use by an Emerging HSR 110mph service will be in a position to take advantage of the higher speed track as soon as it is ready for service.

What Else Needs to be Done

Since what I have been reading is the rule proposal, but the final rule date is given as December 2010, I am not quite sure what has come of this, and due to broken links at the Federal Register, its a bit difficult to work out. That is something I am following up by email to the listed contact.

However, if anything like the proposed rule actually takes affect, this implies a substantial upgrade in the possibilities for using our existing rail corridors. Since this is being done by regulation rather than by waiver, it can be put to use across the board, rather in the piecemeal way implied by waivers of regulations. And since it is being done by regulation, it provides a standing target for the manufacturing of a new generation of more effective and efficient passenger train.

Of course, this is not everything. As Hans-Joachim Zierke notes, the “build it like a tank” approach to crash survival results in heavier trains, while the European and Japanese approach of “design the system to avoid crashes” results in lighter trains, and lighter trains are better able to take advantage of these new cant deficiency regulations than heavier trains.

But this is a good step. And its a first step that may well have been the result of a Republican Take-Over … that is, in 2009 in the Department of Transportation, when Roy LaHood was made Secretary of Transportation and the eight year assault on rail transport by the Bush administration came to an end.

Midnight Oil ~ Kosciusko

Older than kosciusko

Darwin down to alice springs

Dealers in the clearinghouse

The settlements explodeHigh up in the homelands

Miners drive across the land

Encounter no resistance

When the people block the roadOld than kosciusko

Dry white seasons years ago

Darkness over charleville

The fires begin to glowNo end to the hostility

Now they wanna be somehwere else

No stranger to brutality

Now they’d like to be someone else

…

1 comments

Author

… Agent Orange Station that it did not complete the service until Monday evening.

Chalk it down to the long weekend.